To stay in business competitively, every manufacturing company needs to change, to improve continuously. However, this needs to be done while remaining extremely efficient, effective and still compliant to all applicable regulations. A huge challenge!

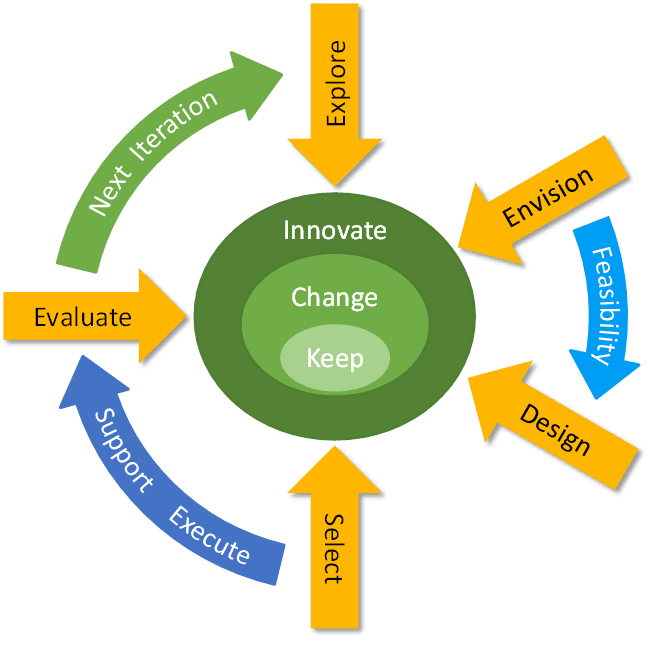

Every company has best practices in their operations that they are proud about and which contribute to their success. Next to that, they have activities that definitely can be done better, can or must be improved. Basically, there are three ways to improve your manufacturing performance:

- Keep: Apply your best practices more often

- Change: Improve your not so good practices

- Innovate: Introduce new technologies and methodologies

To change your manufacturing operations successfully, alignment is required between your processes (ways of working), your organization & governance, the skillsets of your people and the enabling and supporting technologies.

Business Change Cycle

Successful control of the business change cycle requires an appropriate strategy and a structured approach:

- Explore of the improvement potential and creating awareness with your people. Read more …

- Envision your future and create the sound benefits case supporting the investment decision. Read more …

- Design the blueprint for the future including processes, organization & governance, people skillsets and the enabling technologies. Read more …

- Select the right MOM solution (MES, LIMS, PDM/PLM, etc.). Read more …

- Execute the deployment of the solution(s) to obtain sustainable improvements. Read more …

- Evaluate the captured benefits and prepare for the next cycle. Read more …

Control the Business Change Cycle can be applied to:

- Evaluate your current ‘older’ MES/MOM and create a roadmap for improvement

- Increase the quality of your (manufacturing) master data management

- Design the planning, scheduling, and execution processes, select appropriate tools to support these (new) processes or use existing tools differently

- Evaluate your custom manufacturing solution(s) against Out of the Box solutions

- Create a Manufacturing Center of Excellence combining IT and OT